The Low Down On Ink Drawdowns

Ink Drawdowns in printing refer to a process used to visually assess and control the color and consistency of ink before it is applied to a substrate (in our case, typically paper) using a drawdown tool.

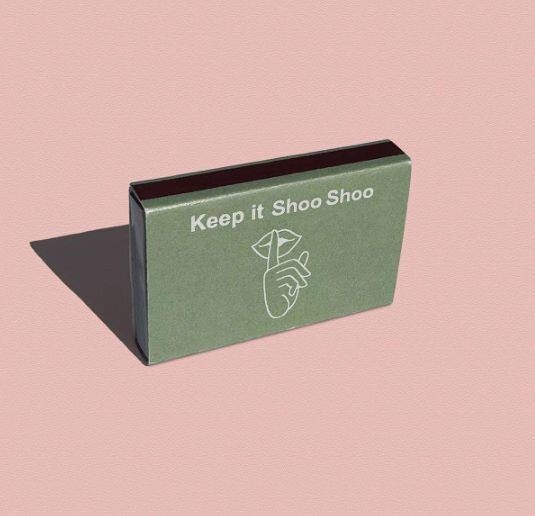

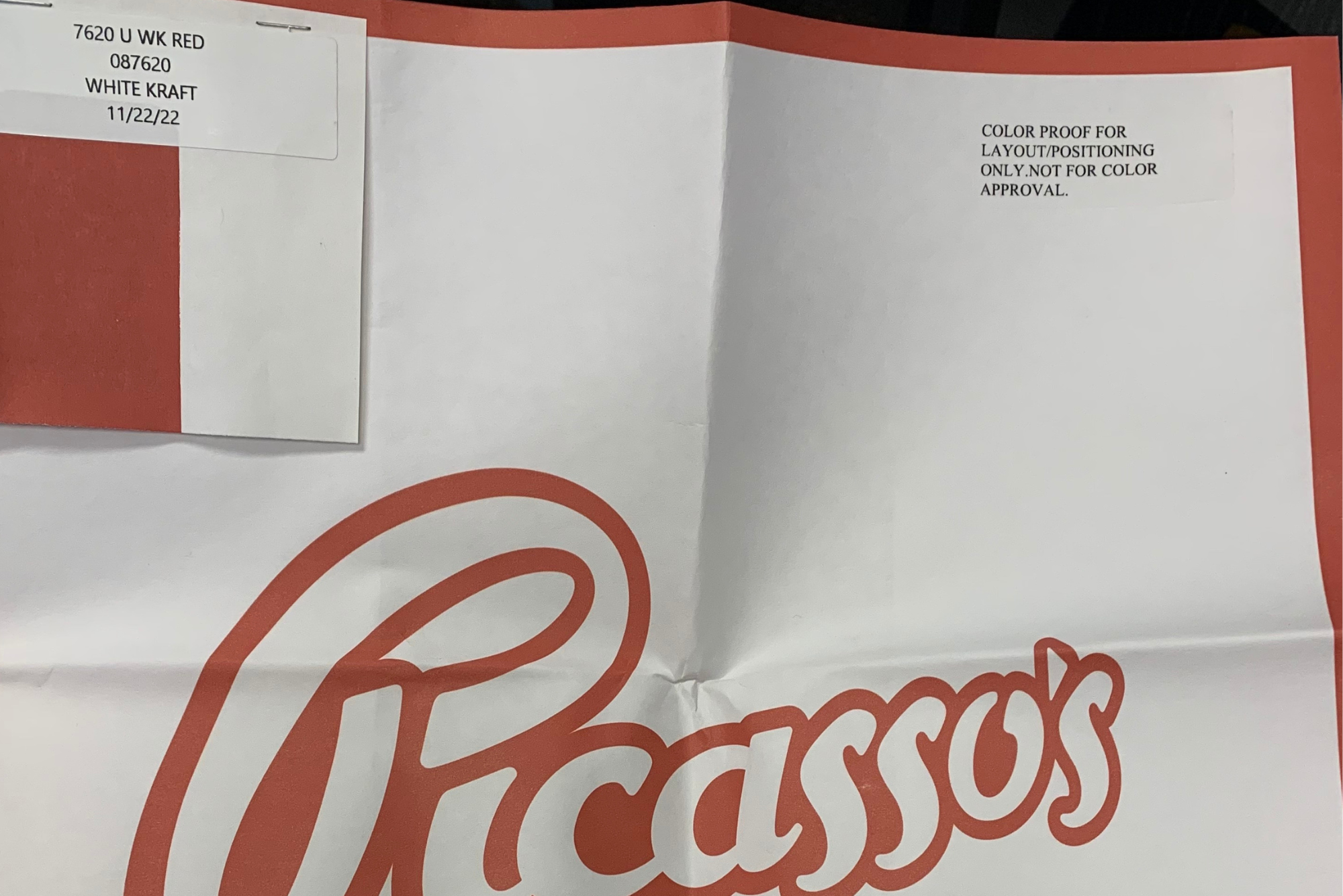

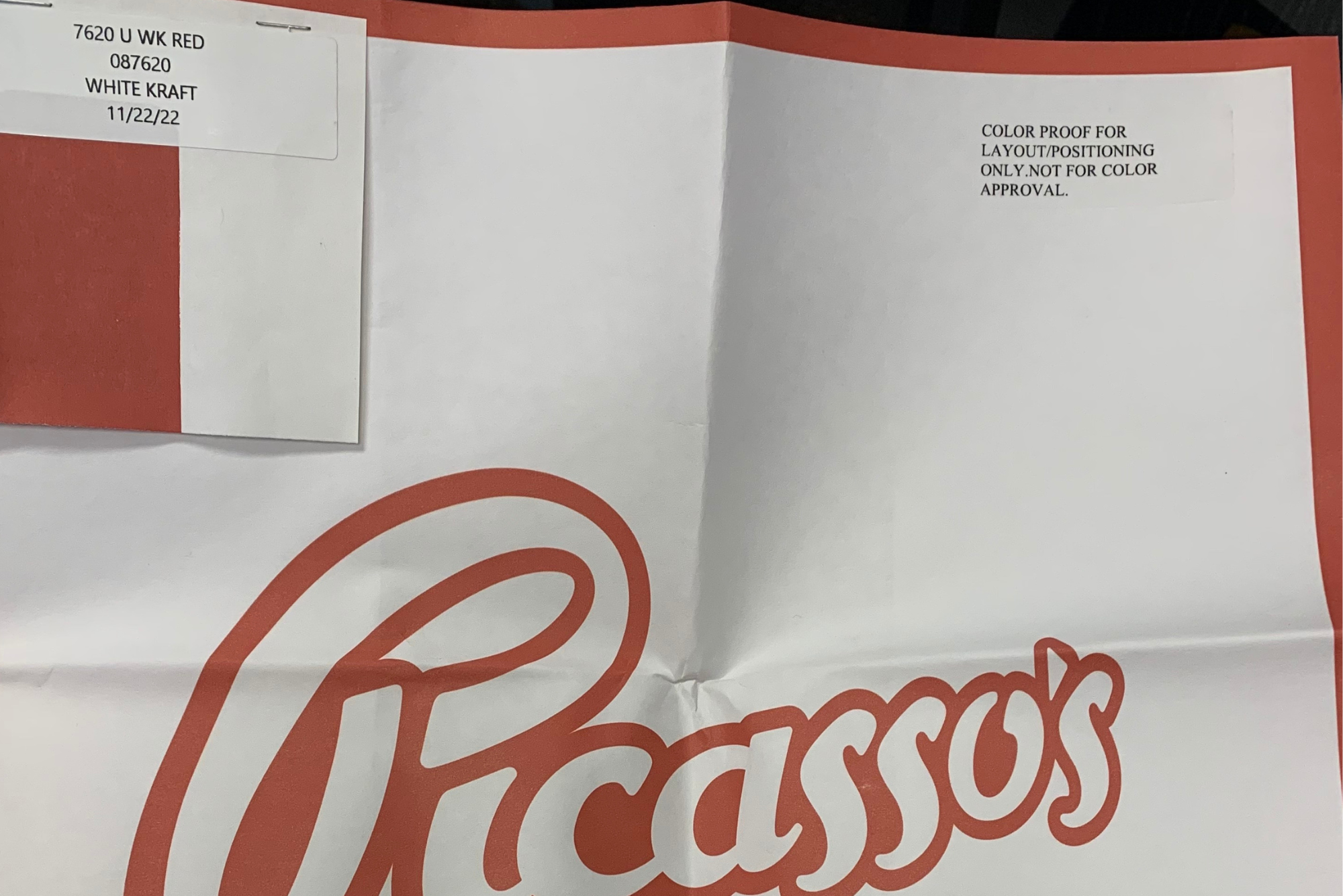

Essentially, we will digitally print the design to show positioning and then include an ink drawdown (just like the image below) to show how your color is going to look on a colored surface. This helps ensure the ink color is accurate and matches the intended color for a particular print job.

Usually these are not needed when printing on white, as there is no impact to your color. However, when you have a Pantone color and you’re printing on a colored surface like kraft or any color, micro parts of the color can get through which actually impacts the end result of how the color will look.

So, if you have a Pantone red and you’re printing on a white takeaway bag, it’s going to look bright red or whatever color you have selected. Print the same color on natural kraft and it will look dull and darker because some of that natural kraft is going to get through.

Ink drawdowns are used to protect against that.

Think of them like an insurance policy between the buyer and supplier understanding how the final color will be displayed before you go on to produce your run of bags.

Overall, ink drawdowns play a crucial role in maintaining color accuracy, consistency, and quality in the printing process, and help printers identify and address potential issues before they impact the final printed materials.