Screen Printing: Getting Your Designs Beyond The Frame

Screen printing, or silk screen printing, is a printing method where a fine mesh screen is stretched across a frame and ink is placed into the screen. Screen printing is done one color at a time. So each screen will be printing only one of the design colors. That’s why you’ll have one screen setup cost per color, per print location. The most common items that use screen printing are t-shirts, hoodies, apparel, reusable water bottles, and metal signage.

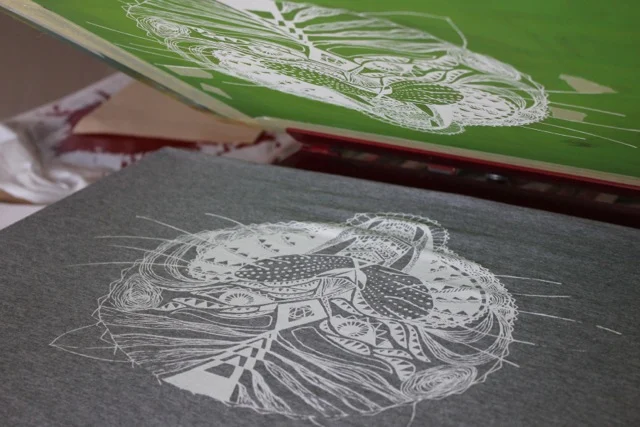

In screen printing, a design is created by blocking off areas of the screen with non-permeable material, and leaving only the desired design open. Next, the ink is spread across the screen using a squeegee onto the fabric or paper creating a print of the design. For a multi-color design, the ink is applied one by one and transferred to the material on the other side.

In the image below you can see the ink being spread across the design on the screen to transfer onto the product below the frame.

Screen printing can be an effective way to create branded merchandise, promotional materials, art, and fabric prints. This printing method allows for the creation of high-quality, long-lasting prints with vibrant colors and crisp details.

Looking to create more prints? Once the screen has been created, they can be cleaned, stored and reused for future projects whether adding to a reorder, or change or update in color. Relatively quick and low cost, screen printing is a reliable print method to produce high-quality and cost-effective products for a wide range of companies.